Mechanics and electronics work together and harmoniously complete each other in our latest product. Heavy Cut sheeters include brushless motors electronically controlled. Changing the paper reel with a Heavy Cut sheeter is easy, fast and ideal for small runs.

The unwinder assembly is composed by a reel management system optimized by shaftless unwinders (no pneumatic shaft) which allow for the rapid loading of the reel. Synchro cut machines can be equipped with a double register control system driven by sensors.

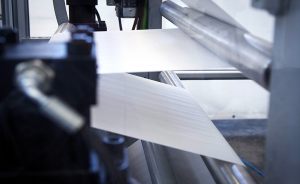

The cut assembly is provided in two versions, based on the customer’s request: death knife (single rotating blade) or synchro (double rotating blades). Besides, blades can be positioned for cross cuts to divide the paper reel in more parts or to trim the edge.

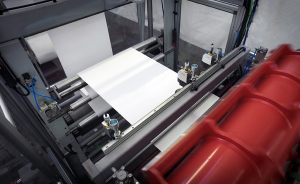

Sheets slide on a double series of conveyor belts to the high-pile collection system (ream maximum height 1400 mm) through an automatic motorized platform which allows for an efficient and precise piling system (equipped with a level indicator to detect the upper edge of the ream). The orthogonality of the ream is ensured by the automatic alignment system of the reels.

10.4” color touchscreen control panel housed in a rotating support aluminium arm. Operators can set up work parameters, display production data, save previous programs, make diagnosis and maintenance and repair operations. Automation is integrated with a web-based diagnostic system, remotely controlled.

On request of the customer, the Heavy Cut Sheeter can be in-line-integrated with an embossing press of our production, printer or laminating machine.

Motors

Action-controls, brushless motors in electric axis (gantry) between them, controlled by an HMI panel.

Unwinder

Double shaftless unwinder (without pneumatic shafts) for the rapid loading of the reels

Check systems

Calibration mark detecting system operated by photocells with register double check

Controls

10.4” color touchscreen control panel housed in a rotating support arm

Cut

Motorized cross-cut assembly with double rotating blade and automatic balancing system

Collection system

High-pile collection tray with thermohydraulic catwalk