Multi Cut

VERSATILITY AND PRODUCTION EFFICENCY

The Multi Cut sheeters represent a new technical frontier

in the converting field, fully encompassing the skills and experience of 4M Refai technicians.

A machine endowed with innovative solutions designed to meet the needs of a market in constant evolution. It adapts to the most varied production needs, guaranteeing considerable competitive advantages compared to the cutting machines currently on the market.

Thanks to its exceptional versatility, which allows a rapid change of format, it is the ideal machine for the production of small runs. An innovative system of ream unwinding management considerably reduces the risk of paper jamming on the blade.

The machine is equipped with a double register control system by means of photocells to cut 2 printed reels simultaneously.

The web can be cut longitudinally into several sections of different widths, allowing the management of different production batches on a single reel.

The cut sheets are conveyed by belts to the collection cylinder, which, depending on the selected number allows to manage the height of the ream unloaded, allowing to obtain reams up to a minimum of 5 sheets.

The reams are then transferred to a rotating table with motorized belts that allows the collection of the ream manually or its transfer to an automatic packaging system.

A machine endowed with innovative solutions designed to meet the needs of a market in constant evolution. It adapts to the most varied production needs, guaranteeing considerable competitive advantages compared to the cutting machines currently on the market.

Thanks to its exceptional versatility, which allows a rapid change of format, it is the ideal machine for the production of small runs. An innovative system of ream unwinding management considerably reduces the risk of paper jamming on the blade.

The machine is equipped with a double register control system by means of photocells to cut 2 printed reels simultaneously.

The web can be cut longitudinally into several sections of different widths, allowing the management of different production batches on a single reel.

The cut sheets are conveyed by belts to the collection cylinder, which, depending on the selected number allows to manage the height of the ream unloaded, allowing to obtain reams up to a minimum of 5 sheets.

The reams are then transferred to a rotating table with motorized belts that allows the collection of the ream manually or its transfer to an automatic packaging system.

MATERIALS

It can process different kinds of products such as wrapping paper, gift paper, laminated paper, PE, PET, BOPP in the weight from 30gsm up to 150gsm

MAIN FEATURES

Motori

12 brushless motors and drives in electric axis between them

Check systems

Double register control, performed by a sensor for mark detection

Controls

10.4” color touchscreen panel, with database to manage cut programs

Cut

Management of different production lots on a single reel

Collection

Innovative sheet collection system that allows to obtain reams up to a minimum of 5 sheets

Stacking

Automatic ream unloading by motorized belts

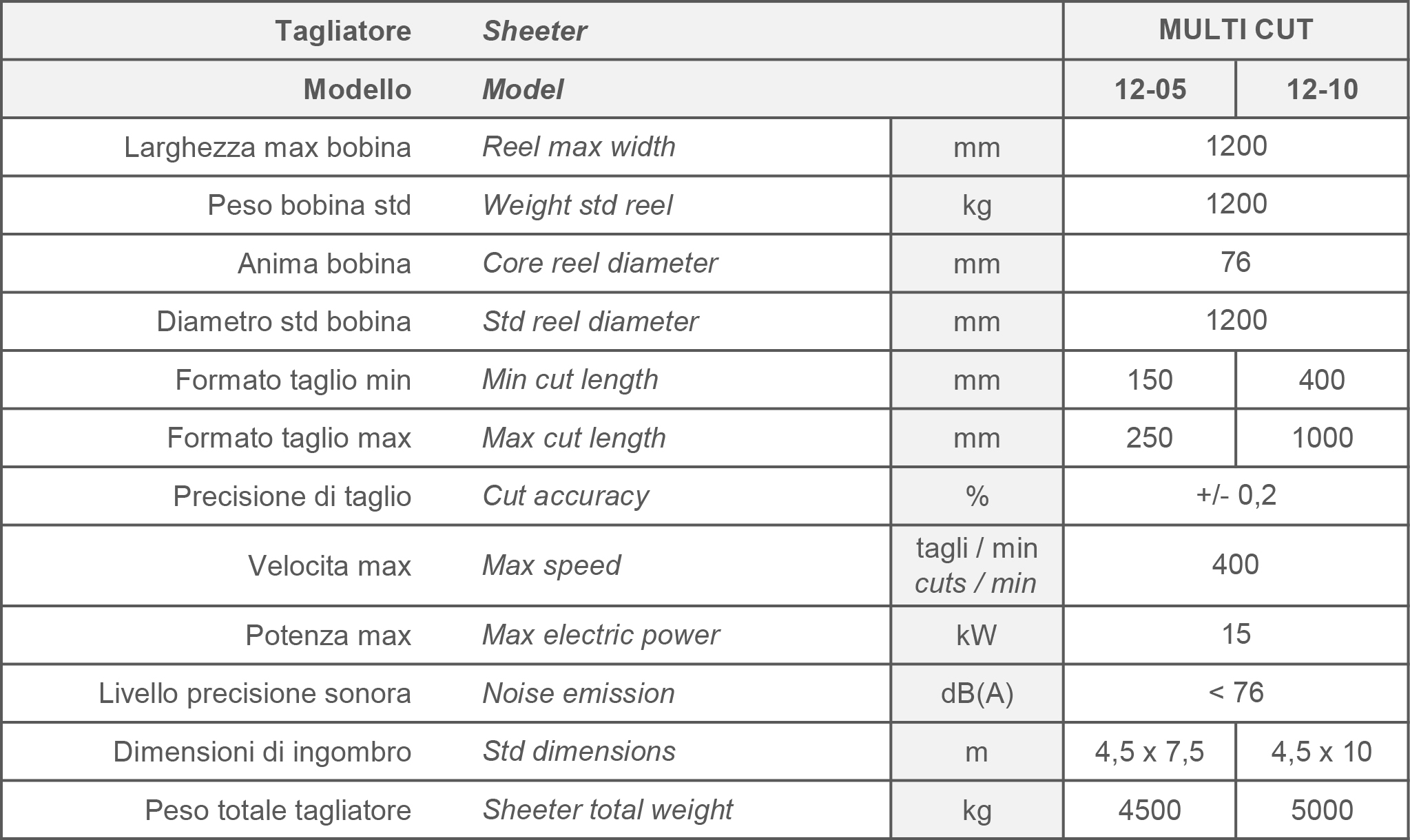

TECHNICAL DATA

GALLERY